Mastering Your Bill of Materials: A Practical Guide for Success

What a clothing BOM is, why it matters, and how to structure it for clarity, cost control, and speed.

In the fast-paced world of clothing production, getting the details right is super important. That’s where the Bill of Materials, or BOM, comes in. Think of it like a recipe for your clothes – it lists absolutely everything you need to make a garment, from the fabric and thread to the buttons and zippers. It’s not just a list, though; it’s a key tool that helps designers, manufacturers, and suppliers stay on the same page, making sure everything gets made correctly and without a lot of waste. Mastering your bill of materials is pretty much essential if you want to make good clothes efficiently.

Key Takeaways

A Bill of Materials (BOM) is a detailed list of all raw materials, components, and instructions needed to create a product, acting as a crucial roadmap for production.

Key components of an effective BOM include precise material specifications, accurate quantities, supplier details, cost breakdowns, and version control.

Structuring your BOM with clear item numbers, descriptions, units of measure, and supplier information makes it easier to manage and communicate across teams and with vendors.

Common challenges like design changes and supply chain complexity can be managed with dynamic systems, clear communication, and strong supplier relationships.

Utilizing digital tools and integrating BOMs with systems like ERP and PLM can automate processes, improve accuracy, and provide better overall management.

Understanding the Bill of Materials in Clothing Production

In the world of making clothes, getting everything right from the start is super important. That's where the Bill of Materials, or BOM, comes in. Think of it as the master plan for your garment. It’s not just a list of stuff; it’s the detailed roadmap that tells you exactly what you need to make a piece of clothing, from the main fabric down to the tiniest thread.

Introduction to Bill of Materials in Clothing Production

So, what exactly is a BOM in the clothing business? Basically, it’s a document that lists every single thing that goes into making a garment. This includes all the materials, like the main fabric, lining, and thread, but also all the little bits and pieces – the buttons, zippers, labels, and even the hang tags. It’s the blueprint that connects the designer’s idea to the actual product you can hold in your hands. Without a solid BOM, you’re basically trying to build something without instructions. It’s the foundation for everything that follows in production.

The Art of Material Planning: Understanding the Bill of Materials in Clothing Production

Getting the BOM right is kind of like planning a big meal. You need to know exactly how much of each ingredient you need, where to get it, and how much it costs. In clothing, this means listing:

Fabric: Type, weight, width, color, and how much you need per garment.

Trims: Buttons, zippers, snaps, hooks, eyelets – their size, material, color, and quantity.

Thread: Type, color, and how much is needed for stitching.

Labels: Care labels, brand labels, size labels – their content and placement.

Packaging: Polybags, hang tags, tissue paper, boxes – what’s needed and how many.

This detailed planning helps avoid running out of something halfway through a production run or having way too much of something else. It’s all about being prepared and organized.

The BOM is more than just a shopping list for your factory. It's a communication tool that ensures everyone involved, from the person sourcing the fabric to the seamstress on the production line, is on the same page. This clarity prevents mistakes and keeps the production process running smoothly.

Why is BOM Crucial in Fashion?

In fashion, things move fast. Trends change, and brands need to keep up. A good BOM is super important for a few reasons:

Accuracy: It makes sure the garment is made exactly as the designer intended. No surprises with the wrong color button or a different type of fabric.

Cost Control: By knowing exactly what materials are needed and how much, you can get a clear picture of the production cost. This helps in pricing the garment correctly and staying profitable.

Efficiency: When you have all the material information upfront, ordering and production planning become much easier. This means fewer delays and less wasted time.

Quality: The BOM specifies the quality of materials and components, which directly impacts the final product's feel and durability. It’s the backbone of consistent quality.

Sustainability: You can use the BOM to track the types of materials used, helping you choose more eco-friendly options and manage your environmental impact. It’s a way to build sustainability right into the product from the very beginning.

Key Components of an Effective Bill of Materials

So, you've got a design, maybe even a prototype, but how do you actually make a bunch of these things without losing your mind or your money? That's where the Bill of Materials, or BOM, really shines. It's not just a list; it's your roadmap for production. Think of it as the recipe for your garment. Without a solid BOM, you're basically winging it, and that rarely ends well in manufacturing.

Detailed Material Specifications

This is where you get down to the nitty-gritty of what your product is made of. It’s not enough to just say 'cotton'; you need to specify the type of cotton, its weight (like grams per square meter or ounces per yard), its width, and even the exact color code. For example, if you're making a t-shirt, you'll list the fabric for the body, the thread for stitching, and any labels or tags. Getting these details right prevents costly mistakes down the line.

Quantity and Sizing Information

Once you know what you need, you have to figure out how much. This section of the BOM details the exact quantity of each material required for a single unit of your product. It also needs to account for different sizes and colorways. If your shirt comes in S, M, and L, and you offer it in blue and red, your BOM needs to reflect the material needs for each variation. This helps immensely with ordering and keeping track of inventory, so you don't end up with way too much of one thing and not enough of another.

Supplier Details

Who are you getting all these materials from? This part of the BOM lists the specific suppliers for each component. It should include their name, contact information, and importantly, the lead time – how long it typically takes for them to deliver the goods. Knowing this helps you plan your production schedule realistically and identify potential bottlenecks before they become major problems. It also makes reordering much simpler.

Cost Analysis

This is a big one. Your BOM should break down the cost of each individual component and material. This allows you to calculate the total cost of producing one unit of your garment. You can see where your money is going, identify areas where you might be overspending, and make informed decisions about sourcing or material choices to stay within budget. It's pretty straightforward:

Fabric Cost: Price per yard/meter multiplied by the quantity needed.

Trim Cost: Cost of buttons, zippers, labels, etc., per unit.

Thread Cost: Estimated cost based on usage.

A well-documented BOM is your best defense against unexpected expenses. It provides a clear financial picture, allowing for better budgeting and negotiation with suppliers. Without it, you're flying blind when it comes to the actual cost of making your product.

Structuring Your Bill of Materials for Clarity

Think of your Bill of Materials (BOM) like a recipe for your product. Just like a chef needs a clear list of ingredients and steps, you need a well-organized BOM to guide manufacturing. Without it, things can get messy, and that's the last thing you want when you're trying to make something. A well-structured BOM is the backbone of efficient production.

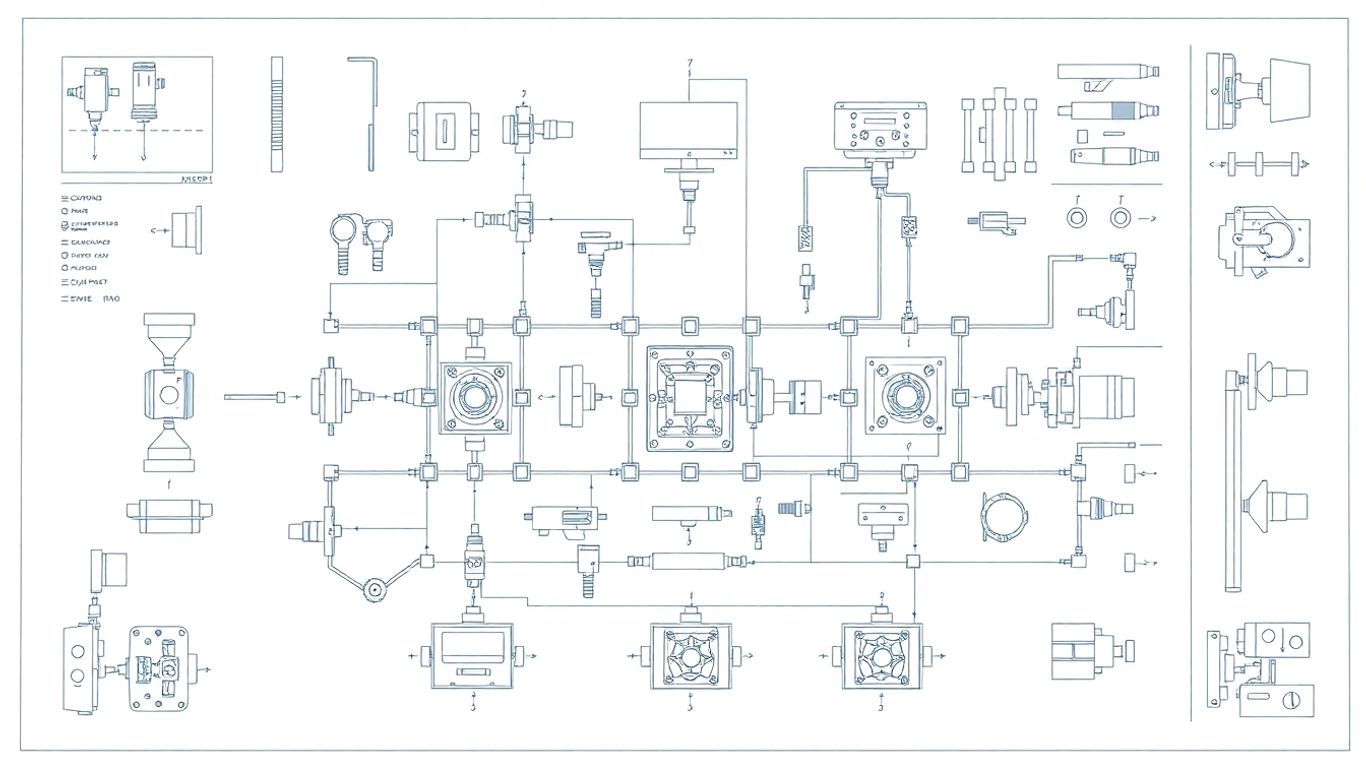

Anatomy of a Basic Bill of Materials

At its core, a BOM is a list. But it's not just any list; it needs specific details for each item. You'll want to include a unique item number, a clear description of what the part is, and how many you need. It's also helpful to note the unit of measure (like 'pieces' or 'meters') and the specific material used. This basic setup helps everyone involved understand what goes into the product.

Hierarchical Structure for Complex Products

For more complicated items, a simple list just won't cut it. You need to break things down. Imagine building a car; you have the whole car, then the engine, then the parts that make up the engine. That's a hierarchical structure. You can use assemblies and subassemblies to organize your BOM. Indentation in your document can really help show how everything fits together, making it much easier to follow.

Here's a simple example:

Item Number | Description | Quantity | Unit | Material | Assembly Level |

|---|---|---|---|---|---|

1000 | Main Product | 1 | Each | N/A | 0 |

1001 | Housing Assembly | 1 | Each | Plastic | 1 |

1001.1 | Front Casing | 1 | Each | ABS | 2 |

1001.2 | Back Casing | 1 | Each | ABS | 2 |

1002 | Electronic Module | 1 | Each | PCB | 1 |

1002.1 | Main Circuit Board | 1 | Each | FR4 | 2 |

Categorization by Engineering Areas of Responsibility

Different teams work on different parts of a product. Mechanical engineers handle the physical parts, while electrical engineers focus on the electronics. It makes sense to organize your BOM based on these areas. This way, the team responsible for the printed circuit boards doesn't have to sift through details about packaging materials, and vice versa. It keeps things focused and efficient.

Organizing your BOM by department or engineering area of responsibility (AoR) is a smart move. It means that when you're talking to a supplier for electronic components, they can easily find all the relevant parts without getting bogged down in details about the outer packaging. This clarity saves time and reduces the chance of miscommunication.

Here are some common categories:

Mechanical Engineering (ME): This includes custom-made parts like molded housings, buttons, and die-cut tapes, as well as off-the-shelf items like screws, speakers, and batteries.

Electrical Engineering (EE): This covers printed circuit boards (PCBs), and all the tiny components that go on them, such as resistors, capacitors, and LEDs.

Packaging & Information: This section lists items like the product box, protective film, instruction manuals, and any labels or stickers.

By using these structures, your BOM becomes a clear, actionable document that everyone can use effectively.

Essential Elements for Your Bill of Materials

Alright, so you've got your design, and now it's time to actually list out everything you need to make it. This is where your Bill of Materials, or BOM, really shines. Think of it like a recipe for your product – without the right ingredients listed clearly, things can go sideways fast. Getting these details right from the start saves a ton of headaches later on.

Let's break down what absolutely needs to be in there:

Item Number and Detailed Description

Every single thing, from the main fabric to the tiniest button or thread, needs its own unique identifier. This isn't just a random number; it's how you'll track each component. Alongside that number, you need a description that's clear enough for anyone to understand what it is and what it does. No vague terms allowed!

Quantity, Unit of Measure, and Material

This is where you get specific. How many of each item do you need? Is it by the piece, the yard, the meter, or the kilogram? You also need to state the actual material. For fabric, this means the fiber content, weight, and width. For a zipper, it might be the length and the type of teeth. Precision here is key for ordering and avoiding waste.

Here’s a quick look at how this might appear:

Item Number | Description | Quantity | Unit of Measure | Material |

|---|---|---|---|---|

FAB-001 | Cotton Jersey Knit | 50 | Yards | 100% Cotton |

TRIM-005 | Zipper, Metal, Black | 100 | Pieces | Metal, Polyester |

BUT-012 | Coconut Shell Button | 200 | Pieces | Coconut Shell |

Supplier Information and Lead Time

Knowing who you're getting your materials from is super important. Include the supplier's name and maybe even their contact info. Equally important is the lead time – how long it actually takes for that material to get to you once you order it. This helps you plan your production schedule way better.

Costing and Revision Level

Each item needs a cost associated with it. This helps you figure out your total product cost and keep an eye on your budget. Also, things change, right? Designs get tweaked, suppliers switch. You need a way to track these changes. The revision level tells you which version of the BOM you're looking at, so everyone's working with the most current information.

Keeping your BOM updated isn't just about accuracy; it's about communication. When your production team, your suppliers, and your design department are all looking at the same, correct information, you avoid costly mistakes and delays. It’s the backbone of efficient manufacturing.

So, putting all these pieces together creates a solid foundation for making your clothing. It’s not just a list; it’s a roadmap.

Challenges and Solutions in Bill of Materials Management

Keeping your Bill of Materials (BOM) in order can feel like a constant battle, especially in the fast-moving fashion world. Designs change, suppliers shift, and costs go up and down. It’s a lot to track.

Keeping Up with Rapid Design Changes

Fashion moves at lightning speed. A design that’s hot today might be old news next month. This means your BOM needs to be updated constantly. If it’s not, you could end up with the wrong materials or outdated costings. The key is to have a system that can handle these quick shifts.

Solution: Use digital tools, like Product Lifecycle Management (PLM) software. These systems let you update the BOM in real-time. When a designer tweaks a sleeve or changes a fabric, that change can be instantly reflected in the BOM. This keeps everyone on the same page and stops costly mistakes.

Managing Complex Supply Chains

Most clothing brands don't make everything themselves. You're likely working with different suppliers for fabrics, buttons, zippers, and more, often across different countries. This makes managing all those parts and where they come from pretty complicated.

Solution: Connect your BOM system with your supply chain management tools. This gives you a clear picture of who is supplying what and when. It helps you coordinate better with everyone involved, from the fabric mill to the factory floor.

Ensuring Material Availability and Cost Control

Sometimes, the fabric you want isn't available, or its price jumps unexpectedly. This can mess up your production schedule and your budget. You need to be ready for these kinds of surprises.

Solution: Keep an eye on the market and build good relationships with more than one supplier for your key materials. This way, if one supplier has an issue, you have backup options. It also gives you more power to negotiate prices.

Maintaining Sustainability and Ethical Standards

Customers care more than ever about where their clothes come from and how they're made. Your BOM needs to reflect this. You have to make sure the materials you list meet certain standards for being eco-friendly or ethically sourced.

Solution: Add information about sustainability and ethical practices directly into your BOM. Track which suppliers meet your standards and which materials are better for the environment. This makes it easier to show customers you're doing your part.

Keeping your BOM accurate and up-to-date isn't just about listing parts; it's about managing risk, controlling costs, and meeting modern consumer expectations. It requires good systems and a clear process for handling changes.

Innovative Tools and Software for Bill of Material Management

These days, keeping track of all the bits and pieces that go into making clothes is way easier thanks to new software and tools. It's not just about listing things anymore; it's about making the whole process smoother and smarter. Using the right tech can really make a difference in how efficiently you produce garments.

Leveraging Digital Tools for Automation

Lots of software now helps automate tasks that used to take ages. Think about automatically updating quantities when a design changes or flagging when you're running low on a specific fabric. This cuts down on mistakes and frees up people to focus on more important stuff. It's like having a super-organized assistant who never sleeps.

Integrating BOM with ERP and PLM Systems

Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) systems are big players here. PLM systems are great for managing everything about a product from start to finish, including the BOM. They let everyone see the latest version and work on it together. When you link your BOM to these systems, it means your material list talks to your inventory, your production schedule, and even your sales data. This connection helps avoid problems like ordering too much of something or not having enough of another.

Here's a quick look at how they connect:

System | How it Helps BOM Management |

|---|---|

PLM | Centralizes product data, tracks design changes, manages revisions. |

ERP | Connects BOM to inventory, production planning, and financials. |

SCM | Integrates supplier information and material availability. |

The Evolution of BOM with Technology

Technology is constantly changing how we handle BOMs. Artificial intelligence (AI) and machine learning are starting to pop up, helping to predict material needs or suggest better suppliers. Cloud-based tools mean you can access your BOM from anywhere, which is a lifesaver for teams spread out geographically. Even 3D design software is getting involved, letting designers see how materials will look and work in a virtual model, which then feeds directly into the BOM. It's all about making the BOM a living document that keeps pace with the fast-moving fashion world.

Best Practices for Bill of Materials Accuracy

Keeping your Bill of Materials (BOM) accurate is like making sure your recipe has all the right ingredients in the correct amounts. If it's off, your final product won't turn out as planned, and that can get expensive fast. So, what's the secret sauce to keeping your BOM in tip-top shape?

Regular Review and Updates

Think of your BOM as a living document. Designs change, suppliers switch, and material costs fluctuate. You can't just set it and forget it. It needs regular check-ups. Schedule time, maybe monthly or quarterly, to go through each BOM. Look for anything that doesn't match what's actually happening on the factory floor or in your inventory. This proactive approach to BOM management is key for keeping things running smoothly. It's also a good idea to have a clear process for how changes get approved and documented. This helps avoid confusion later on.

Version Control and Change Management

When you make a change to a BOM, it's important to know exactly when that change happened and why. This is where version control comes in. Every time you revise a BOM, give it a new version number. Keep old versions handy, too. This way, if there's a problem with a new batch of products, you can easily go back to a previous, known-good BOM to see what might have changed. It's like having a history book for your product's components. This helps immensely when you need to track down issues or understand the evolution of a design.

Verifying Quantities and Components

This is where you really need to get down to the nitty-gritty. Double-check every single quantity listed. Are you ordering too much of something, leading to excess inventory? Or worse, not enough, causing production delays? Also, make sure everything is listed. Don't forget the small stuff like buttons, zippers, thread, or even the care labels. These little items can cause big headaches if they're missing. A detailed BOM should account for every single piece needed to create the final garment. It's about being thorough, so you don't face unexpected shortages or surpluses.

Accuracy in your BOM isn't just about numbers; it's about building trust with your suppliers and your production team. When everyone is working from the same, correct information, the whole process becomes much more predictable and less stressful. It saves time, money, and a whole lot of headaches down the line.

Wrapping It Up

So, we've gone through a lot about Bills of Materials, or BOMs. It might seem like just a list of stuff, but really, it's the backbone of making pretty much anything. Getting your BOM right means fewer mistakes, less wasted money, and happier customers. Whether you're making clothes, gadgets, or anything else, paying attention to the details in your BOM is super important. It helps keep everyone on the same page, from the person designing it to the folks actually putting it together. Plus, with all the new software out there, managing these lists is getting easier. Keep your BOMs updated, check them often, and you'll be way ahead of the game. It’s not just about listing parts; it’s about smart planning for success.

Ready to run inventory on autopilot?

Flip tracks items, alerts low stock, and simplifies orders—see it on the homepage.

Frequently Asked Questions

What exactly is a Bill of Materials (BOM) in clothing?

Think of a BOM as a detailed recipe for making a piece of clothing. It lists every single thing you need, like the type of fabric, how much of it, the thread color, buttons, zippers, and even the labels. It’s like a shopping list and an instruction manual all in one for creating the garment.

Why is having a BOM so important for fashion brands?

A BOM is super important because it makes sure everyone involved in making the clothes knows exactly what to use and how much. This helps avoid mistakes, saves money by not buying too much material, and makes sure the final product looks just like the designer wanted. It keeps things organized and efficient.

What are the most crucial parts of a good BOM?

The most important parts are clear descriptions of each material (like fabric type, color, and weight), the exact quantity needed for each size, where to get the materials from (supplier info), and how much each item costs. Having a version number to track changes is also key.

How can I make sure my BOM stays accurate, especially with design changes?

The best way is to regularly check and update your BOM whenever a design changes. Using special software can help manage these updates and keep track of different versions. This way, everyone is always working with the most current information.

What challenges might I face when managing a BOM?

You might find it tricky to keep up with quick design changes, manage many suppliers from different places, make sure you have enough materials without having too much, and control costs. Also, making sure the materials are sourced ethically and sustainably can be a challenge.

Are there any tools that can help me manage my BOM better?

Yes, absolutely! There's special software designed to help with BOMs that can automate many tasks and reduce errors. Many companies also connect their BOM systems with other business software, like those for managing resources (ERP) or the entire product lifecycle (PLM), to make everything work together smoothly.